Product Description

Product Specification:

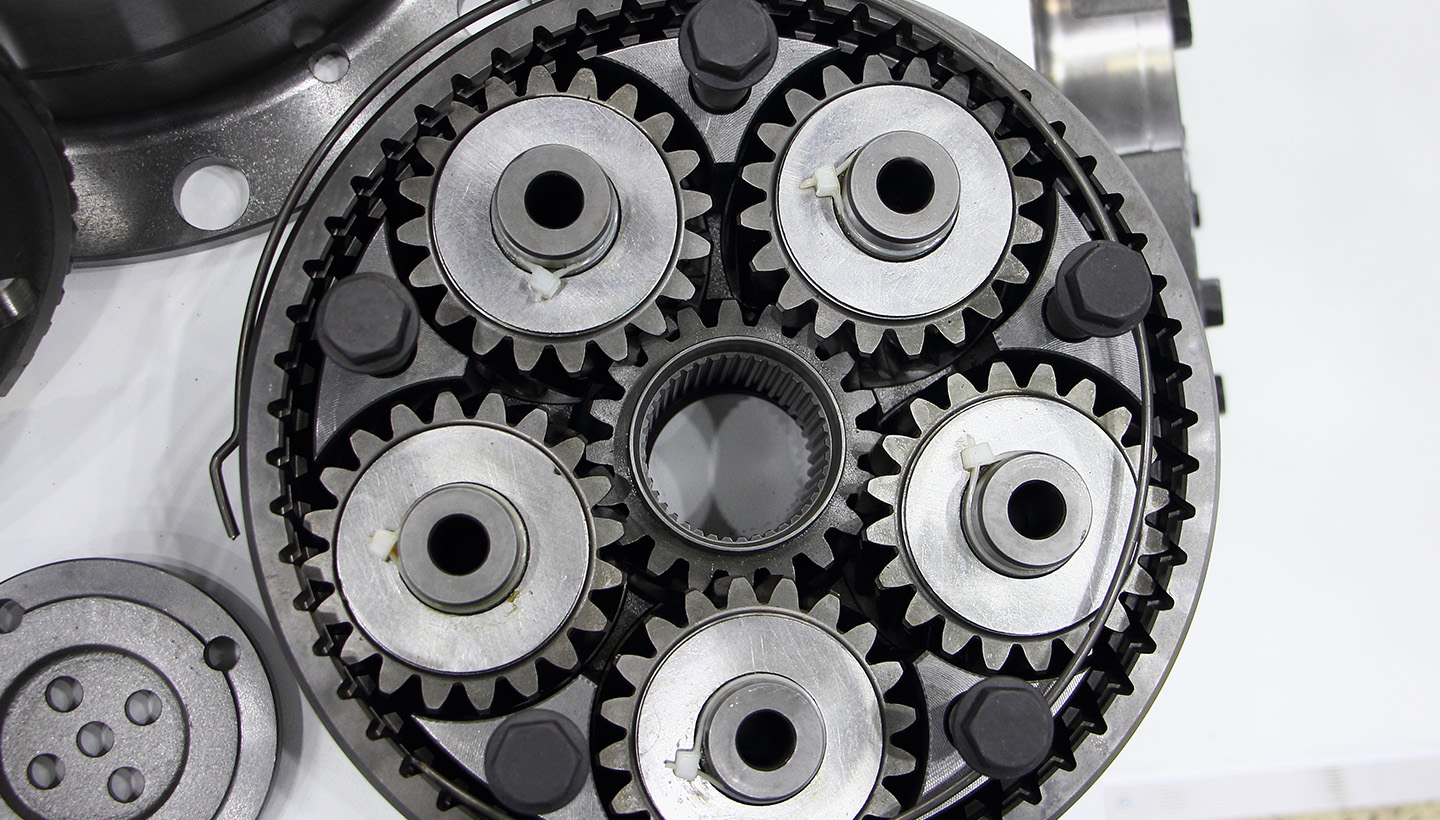

| Title | LiuGong CLG614 rear axle part 41A0034 sun gear |

| Part Name | Sun gear |

| Part No. | 41A0034 |

| Brand | LiuGong |

| Condition | Original/genuine parts |

| Net Weight | 2.7 KG |

| Packaging | Safety carton or wooden box |

| Delivery time | 2-5 working days |

Company Profile:

ZheJiang CHINAMFG Machinery Equipment Co., Ltd is 1 of the wholesaler, which specializes in providing LiuGong spare parts in China.

Our product range as following.

-

Parts for LiuGong wheel loader CLG835, ZL 30E, CLG842, ZL40B, ZL50C, ZL50CN, CLG856, CLG855, CLG862, CLG877 etc..

-

Parts for LiuGong excavator CLG205C, CLG915C, CLG916D, CLG920D/922D/923D/925D, CLG926LC etc..

-

Parts for LiuGong motor grader CLG414, CLG416, CLG418, CLG420.

-

Parts for LiuGong roller CLG612H, CLG614H, CLG618H, CLG614, CLG620 etc..

-

Parts for LiuGong compact wheel loader CLG816/816G, CLG820C, CLG836 etc..

-

Parts for LiuGong skid steer loader CLG365A, CLG375A

-

Parts for LiuGong backhoe loader CLG766, CLG777

-

Parts for LiuGong forklift CPC30, CPC35, CPCD30, CPCD 35 etc..

-

ZF transmission 4WG-200, 6WG-200, 4WG-180, 6WG-180.

-

PERMCO hydraulic pumps

We also have engine parts available for LiuGong machines. If you have any interest or enquiry of LiuGong parts, welcome to contact us.

Know more information, please visit to : http://liugongparts

Warehouse & spare parts pictures :

Packaging pictures

Our advantages & Services

1. Our company in the city where is liuGong factory/headquarter located, spare parts are taken from LiuGong warehouse directly.

2. Our company sell LiuGong genuine spare parts, complying with highest LiuGong performance standards.

3. Our company have own warehouse, which will guarantee you the high availability and short lead time (normal order 1-5 working days ).

4. Our team has rich experience in LiuGong spare parts.

5. Provide flexible pricing, offer discount and deferred payment for the wholesale buyers.

6. Accept payment by T/T and western union.

7. Accept terms of FOB, CIF, CPT ……etc.

If you want to know more infomation, please feel free to call or email us.

| After-sales Service: | Yes |

|---|---|

| Warranty: | Yes |

| Type: | Sun Gear |

| Application: | Liugong Roller |

| Condition: | New |

| Stock: | in Stock |

Can sun gears be used in renewable energy systems?

Sun gears can indeed be used in renewable energy systems, particularly in applications that involve the conversion and transmission of mechanical power. Let’s explore how sun gears can be utilized in different types of renewable energy systems:

- Wind Turbines:

In wind turbines, sun gears can be employed as part of the gearbox mechanism. The gearbox is responsible for increasing the rotational speed of the wind turbine’s rotor to generate electricity efficiently. Sun gears, along with other gears such as planet gears and ring gears, can be used to achieve the desired gear ratios and torque amplification. By leveraging sun gears, wind turbines can convert the relatively low rotational speed of the rotor into the higher rotational speed required by the generator, which produces electricity.

- Solar Tracking Systems:

Sun gears can also play a role in solar tracking systems, which are used to maximize the energy generation of solar panels by orienting them towards the sun throughout the day. These systems often utilize gears to control the movement of the solar panels. Sun gears can be incorporated into the gear mechanism to enable precise tracking and adjustment of the solar panels’ position, ensuring optimal sunlight exposure and energy capture.

- Hydroelectric Power Plants:

In hydroelectric power plants, sun gears can be employed in the turbine and generator systems. These systems use the force of flowing or falling water to drive turbines, which, in turn, generate electricity. Sun gears can be part of the turbine’s gearbox, enabling the efficient conversion of the low-speed rotation of the turbine into the high-speed rotation required by the generator. By utilizing sun gears, hydroelectric power plants can enhance the power generation capabilities of the turbines.

- Wave and Tidal Energy Converters:

Wave and tidal energy converters harness the power of ocean waves and tides to generate electricity. Sun gears can be utilized in the transmission systems of these converters. They can help convert the slow, oscillating motion of the waves or tides into a higher rotational speed suitable for driving generators. By incorporating sun gears, these converters can optimize the energy extraction process and improve the efficiency of power generation.

- Geothermal Power Plants:

In geothermal power plants, sun gears can be used in various components of the energy conversion process. Geothermal power plants extract heat from the Earth’s interior to generate electricity. Sun gears can be employed in systems such as turbines and generators, where they facilitate the conversion of thermal energy into mechanical and electrical energy. By utilizing sun gears, geothermal power plants can enhance the efficiency and performance of the energy conversion systems.

In summary, sun gears can find applications in renewable energy systems such as wind turbines, solar tracking systems, hydroelectric power plants, wave and tidal energy converters, and geothermal power plants. By leveraging the functionality of sun gears, these systems can optimize power generation, increase efficiency, and contribute to the sustainable utilization of renewable energy sources.

Can sun gears be used in high-torque applications?

Sun gears can indeed be used in high-torque applications and are commonly employed in various mechanical systems that require substantial torque transmission. The design and characteristics of sun gears make them capable of handling significant torque loads. Here’s an explanation of why sun gears can be used in high-torque applications:

- Central Positioning: Sun gears are typically located at the center of planetary gear arrangements. This central positioning allows them to distribute torque to multiple planet gears, which then transfer the torque to the outer ring gear. The central position of the sun gear enables efficient torque transmission and load sharing among the gears, making it suitable for handling high-torque applications.

- Torque Amplification: The arrangement of sun gears in a planetary gear system allows for torque amplification. By utilizing the interaction between the sun gear, planet gears, and ring gear, the gear system can multiply or reduce torque based on the gear ratio configuration. In high-torque applications, this torque amplification capability of sun gears is advantageous as it allows for the multiplication of input torque, resulting in higher torque output.

- Sturdy Construction: Sun gears are designed to withstand high torque forces. They are usually made from durable materials such as hardened steel or other alloys with high tensile strength. This robust construction ensures that sun gears can effectively handle the transmitted torque without experiencing excessive wear or deformation.

- Load Distribution: The interaction between the sun gear, planet gears, and ring gear in a planetary gear system enables effective load distribution. By distributing the torque across multiple planet gears, the load is shared, reducing the stress on individual gears. This load distribution mechanism enhances the overall durability and torque-handling capacity of the gear system, making it suitable for high-torque applications.

- Customizable Gear Ratios: Sun gears in planetary systems allow for the customization of gear ratios. By changing the number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, the gear ratio can be tailored to meet specific application requirements. This flexibility in gear ratio control enables the optimization of torque output for high-torque applications.

In summary, sun gears can be effectively used in high-torque applications due to their central positioning, torque amplification capability, sturdy construction, load distribution mechanism, and customizable gear ratios. These characteristics make sun gears reliable and suitable for transmitting substantial torque in various mechanical systems.

What is the significance of the positioning of the sun gear in planetary gear arrangements?

The positioning of the sun gear in planetary gear arrangements holds significant importance and directly impacts the functionality and performance of the gear system. Understanding the significance of sun gear positioning helps in comprehending how different configurations can be utilized to achieve specific objectives. Here’s an explanation of the significance of the positioning of the sun gear in planetary gear arrangements:

- Power Input: The sun gear serves as the primary power input element in a planetary gear arrangement. Its central position allows it to receive rotational motion and torque from an external source, such as an engine or motor. Being the input gear, the sun gear plays a crucial role in transmitting power to other gears within the system.

- Interaction with Planet Gears: The positioning of the sun gear at the center of a planetary gear arrangement enables its engagement with multiple planet gears. The planet gears, which are smaller gears surrounding the sun gear, mesh with both the sun gear and an outer ring gear. This interaction between the sun gear and planet gears facilitates the transfer of torque and motion between the gears.

- Torque Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. The positioning of the sun gear, along with the arrangement of the planet gears and ring gear, allows for torque distribution among the gears. This torque distribution mechanism enables efficient load sharing and prevents excessive stress on any single gear, enhancing the overall durability and performance of the gear system.

- Gear Ratio Control: The positioning of the sun gear in relation to the planet gears and the ring gear determines the gear ratio of the planetary gear arrangement. By changing the arrangement and sizes of these gears, different gear ratios can be achieved. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, play a crucial role in determining the gear ratio. This flexibility in gear ratio control allows for the customization of output speeds and torque levels to suit specific application requirements.

- Torque Amplification: The positioning of the sun gear in a planetary gear arrangement enables torque amplification. By utilizing the interaction between the sun gear, planet gears, and ring gear, the gear system can multiply or reduce torque based on the gear ratio configuration. This torque amplification feature is particularly advantageous in applications where high torque output is needed, such as automotive transmissions and heavy machinery.

- Directional Control: The positioning of the sun gear also contributes to the directional control capability of a planetary gear arrangement. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to the gear system, allowing it to be used in various mechanical applications.

In summary, the positioning of the sun gear in planetary gear arrangements is significant for power input, interaction with planet gears, torque distribution, gear ratio control, torque amplification, and directional control. The central position of the sun gear enables efficient power transmission, load sharing, and customization of gear ratios, making planetary gear arrangements with a sun gear suitable for a wide range of mechanical applications.

editor by CX 2023-10-17